FAQs

How should I care for my hardwood door?

Wood door maintenance really depends on direct sun/water exposure. The frequency of door maintenance varies with individual applications. A door without an over hang or porch is going to weather quicker than a covered door. The bottom line is every few months, look for dulling in your finish which is usually the result of sun burning your door. The sun’s ultra violet rays are bad things, but no worse on doors than anything else. We recommend that your door be wiped down or rinsed off. When pollutants accumulate on the finish, they are often very acidic and will really wear down a finish. You should always check for cracks in the caulk around your door unit, but this is no different for a wood or metal door. As a rule of thumb, every 12 to 18 months the exterior of a door should receive a light sanding with fine sand paper, about 220 grit. After this, one should take a clean cloth, apply a little paint thinner to it and thoroughly wipe the door off. After the door dries for a few minutes, apply a single top coat of polyurethane. When applying polyurethane, brush it on. Please do not short cut and try the aerosol cans. It is important to get a complete coating on the door and do not be afraid to let the polyurethane drip into crevices and cracks to keep the door sealed for best protection against water damage. Voila, the door is good for another 12 to 18 months. It really is that simple.

Always remember, wood came from a living breathing tree and it is more sensitive to the elements than metal, but it is far more beautiful. It will change and grow in character over its life. With just modest attention and care, a wood door can last for many, many years.

How to install a front door with 2 sidelights:

Play Video

Play VideoGreat video explaining how to install a front door with two sidelights.

GLASS: When is a defect not a defect?

Learn more...

Learn more...Quick Answer:

Move away from the glass.

Stand back 10 feet.

Face the glass straight-on at 90 degrees.

View in daylight but not direct sunlight.

Inspect the central 80% portion of the glass.

Under these conditions, if you can’t see it from 10 feet – it isn’t a defect.

That’s the short version.

Why Wood?

Finely crafted wood doors are a source of individual expression and beauty in domestic and commercial architecture. Wood has the ability to adapt to many designs, allowing for thousands of creative possibilities. Wood sets the standard for all other door types to achieve. But no other material delivers the architectural detail, precise shadow lines and mesmerizing grain patterns of wood.

The inherent warmth of wood doors is due to millions of naturally occurring, tiny honeycomb cells between the fibers, which provide a relatively high percentage of air volume, an excellent insulator. According to WDMA sources, wood's insulating properties are 600 times more effective than those of steel. And because wood doesn't conduct hot or cold like most man-made materials, the possibility of "thermal bowing" is diminished. Thermal bowing is caused by extreme temperatures, when one surface of the door is very cold at the same time the other side is very warm. When the cold side of the door contracts and the warm side expands, the uneven pressure that results may cause the structure to bow. Wood is much less susceptible to this problem.

Mortise vs. Tubular Locksets

Play Video

Play VideoDifferent Lock Bodies:

At first glance, the locks may not look all that different from each other. However, if you take a look on the edge of the door you will see the most apparent difference: the lock bodies.

Mortise locks have a single long and rectangular lock body whereas the Tubular locks have two separate cylindrical pieces that fit inside of bored holes.

A few other significant differences to note are variances in security and price. Mortise locks are more secure due to two handy features, anti-saw inserts and the anti-pick security latch. These give your home greater protection against intruders.

Conversely, the Tubular locks do not include these features. Which is not to say that Tubular locks are not secure, however, they just don’t contain those extra means of protection.

With the greater security, comes a higher price. Mortise locks are typically sold for a greater amount than Tubular locks.

Stainless Steel Handle Pulls and Hardware Maintenance

Stainless Steel is rust-resistant due to the alloy components of chrome and nickel. Regular care and maintenance, however, are still required to ensure the longevity and appearance of this material. Since the base material is a form of steel, surface staining can occur in aggressive environments and/or when contact with other metals or materials. Wash surfaces seasonally with warm, clean water and a mild detergent followed by a thorough rinse with clean water especially when surface deposits are visible. If any surface staining does occur, use only a stainless steel cleaner to remove the staining per the manufacturer's instructions. DO NOT use household cleaners, abrasive cleansers, or steel wool at any time to clean the surface.

For added corrosion protection in highly aggressive environments, clean hardware surfaces as noted above and carefully apply Boeshield T-9 as needed. DO NOT allow Boeshield T-9 to contact wood surfaces or other surfaces that tend to absorb oils as staining may occur. Wipe any excess.

Door protection during remodeling and construction:

Doors installed during a home remodel or construction should be protected from construction traffic. However, never seal door behind an air tight vapor barrier as severe damage can occur to your door from excessive heat build up from the solar heat gain of sun exposure. No warranty applies to doors experiencing such conditions. The same applies to the installation of air tight storm doors over a wood door, steel door or fiberglass door.

Handling, Installing and Finishing:

Finishing tips

Finishing tips- Entrance doors shall always be stored on edge, supported vertically (not leaning). Interior doors must be stored flat, in a clean, dry environment.

- Doors shall not be exposed to excessive heat, dryness, humidity, or direct sunlight prior to finishing.

- Handle door with clean gloves and do not drag doors across each other or other surfaces.

- Deliver doors to the jobsite after plaster is dry. If doors are stored on the jobsite for more than one week, all edges must be sealed.

- All hardware locations, preparations, and methods of installation must be appropriate for the specific door.

- All doors 7' and under must have 3 hinges. Doors over 7' must have 4 hinges.

- Prior to finishing, remove all handling marks with 150 grit or finer sandpaper and remove all sanding dust.

- Apply sealer, primer, or first coat of required finish immediately after fitting, cutting for hardware, weatherstripping, etc. and before the installation of hardware or hanging the door.

- All exposed surfaces of the door must be sealed, including the top, bottom, side edges, and the hardware cutouts.

- Use only oil-based stains, sealers, or primers on the door. If water-based paint is to be used, it must be applied over an oil-based primer. (Note of Caution: An interior grade lacquer is NOT a satisfactory product for exterior use.)

- All exterior surfaces, including the top, bottom, and sides of the door must be finish coated with a good quality exterior grade paint or varnish. At least three (3) coats of exterior grade varnish with a UV Inhibitor must be applied.

- In order not to induce warpage or excessive deterioration of your door, avoid using dark stains or paints on the door surfaces exposed to direct sunlight.

- Most finishes on exterior doors deteriorate relatively quickly. To insure exterior doors receive the protection required, inspect the condition of exterior finish at least once a year and refinish as often as needed to maintain the protective stability of the finish.

Wood is easily planed at the home site to fit odd-sized openings. Imperfections in framing and jamb systems are not the roadblocks that they might be for non-wood, less-adaptable door materials. In addition, shavings from planing a wood door are much less irritating than fibers and other debris from man-made materials. Wood doors, when prepared properly at the home site, take stain evenly and beautifully. In this way, wood is more forgiving than non-wood surfaces.

“Do not use wood conditioners prior to staining mahogany, oak, cherry. Conditioner is good on woods with wild grain variations and most softwood products. On hardwoods, it most often seals the wood and prevents your stain from doing its job and penetrating the wood grain. Your finishes will tend to be light and off color.”

Like anything worthwhile, wood doors require care. We recommend you install wood entrance doors under an overhang that blocks the sun. When finishing the door, all six sides, (four edges and two faces), must be properly sealed, per manufacturers instructions. Avoid applying dark-colored paint, as it is more prone to noticeable fading in the sun. Inspect your wood door every one to two years.

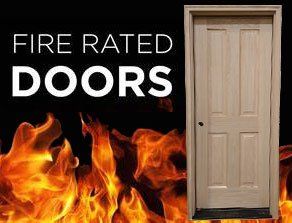

Fire-rated door option:

Contact us for details

Contact us for detailsWe can do most any door style for you in a 20 minute fire rated door (required nationally between your home and your attached garage). Up charge will apply.

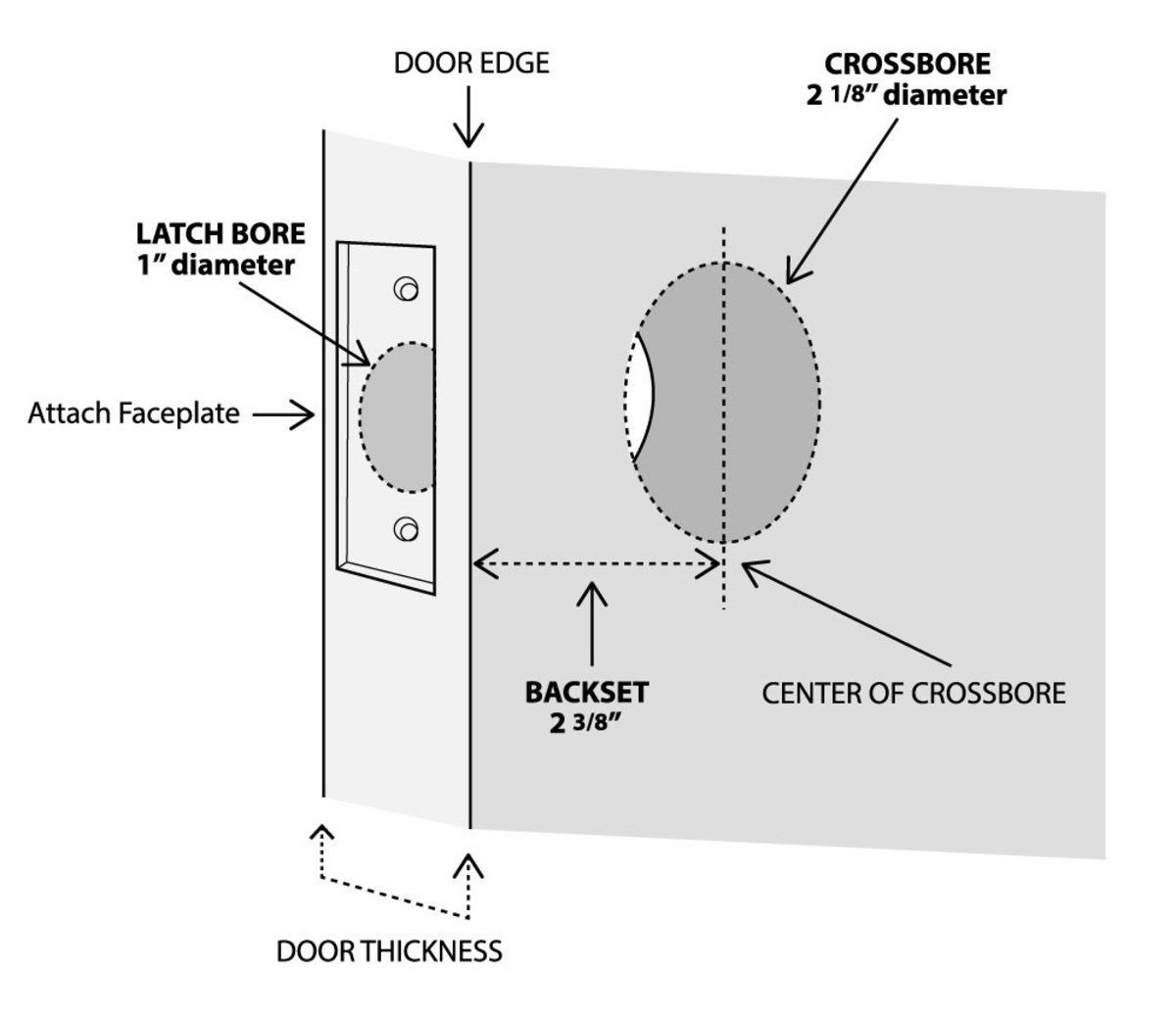

Setback for bore option:

Our lock set bore is backset to 2-3/8”.

Do you have any impact rated door systems that would meet Florida building code?

Structural test video

Structural test videoYes, we can do DP-50 rated structural. We do not often do impact glass, but have doors for coastal applications.

*All doors shipping to Florida areas requiring DP rating will have $475 added to the price because they require special frames, sills & hardware to pass code.

Management of timber concessions:

The mills used for the production of Phirst & Lassing™ doors only utilize timber from government controlled forests. There is strict control over the harvesting and replanting of timber used in every Phirst & Lassing™ door. We can supply, upon request, government letters of certification to confirm that programs are in effect to protect the forest.

Rain forest policy:

We are committed to the protection of the Rain Forest. Strict compliance is maintained with all foreign government regulations to protect the Rain Forest. None of the timber used to produce Phirst & Lassing™ doors is listed as endangered.